|

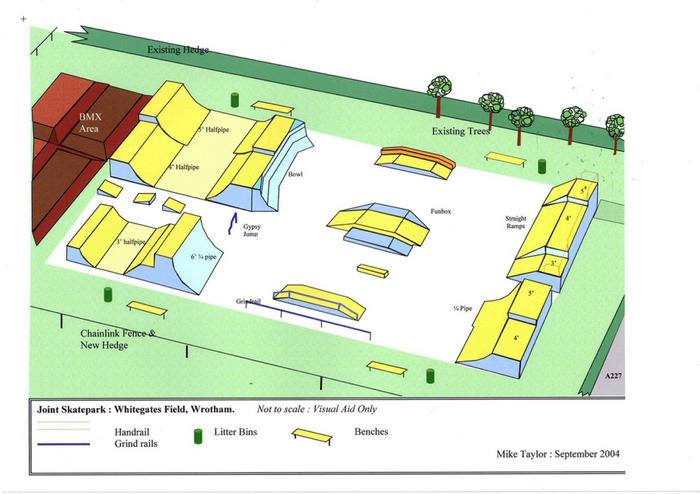

The Design Process for a DIY skatepark The sketch below is the skatepark we are building, and below that the finished product. Through a process of skateboarders talking, making models, collecting ideas from the Web and other parks, we have arrived at this seventh version of the plan. The base is powerfloated concrete, 33mtrsx17mtrs, with all the expansion joints adjusted to minimise uneveness to the surface, this gives a surface that is as smooth as glass. The base was built by a local plant-hire company, Trodell Plant, and they included drainage and the access path in their generosity. We have tried for a design that has gentle enough features for absolute beginners, but with enough difficult bits to be challlenging to experienced skateboarders. Another idea that came out of discussions with BMXers, and also illustrates our stinginess, is that all the excavated soil will be banked at one end and sculpted into a BMX rough area. |

||

|

Computer Geeks!!! The sketch plan of the skatepark was created using the standard Microsoft Word program in XP: it took a bit of working out to begin with : who needs autocad 3D design packages?? |

|

|

Very early prototypes! This photo shows early prototypes for a 4' quarterpipe and a funbox. This helped us to discover that the quarterpipes needed extra bracing because the combined stress of the bends in the flat steel formers and the three layers of ply were trying to "straighten out" the rest of the frame. Will is pictured with his arm in a sling after discovering that he is a better skateboarder than BMXer! He's decided to stick with four wheels, tarmac doesn't give way when hit by a small boy. |

||

|

I told you it was tough enough...... For the diminishing minority who thought my designs weren't strong enough- here is proof positive, van weighs about 1.25 tonnes part loaded, we couldn't drive it right over because the undercarriage fouls on the transforms, |

|